Truck wheels are crucial for safe and efficient vehicle operation. Regular maintenance not only extends the lifespan of components but also detects potential issues early, preventing accidents during cargo transport. This guide from Xe Tai My Dinh provides a comprehensive truck wheel maintenance process, helping you understand the necessary steps to care for your truck’s “feet.”

Regular Truck Wheel Maintenance Procedure

For stable and safe truck wheel operation, maintenance should be performed regularly, usually every 6 months or after a certain number of kilometers, depending on the manufacturer’s recommendations and actual operating conditions. Here are the detailed steps in the truck wheel maintenance process that you should be aware of:

1. Lubricating and Replacing Wheel Bearing Grease (or Wheel Oil)

For truck wheels using bearings, maintenance includes periodic grease replacement. If the wheel uses planetary gears, gear oil needs to be replaced. Continuous operation and high temperatures from friction gradually reduce the lubricating properties of the grease and oil, while also creating small metal particles.

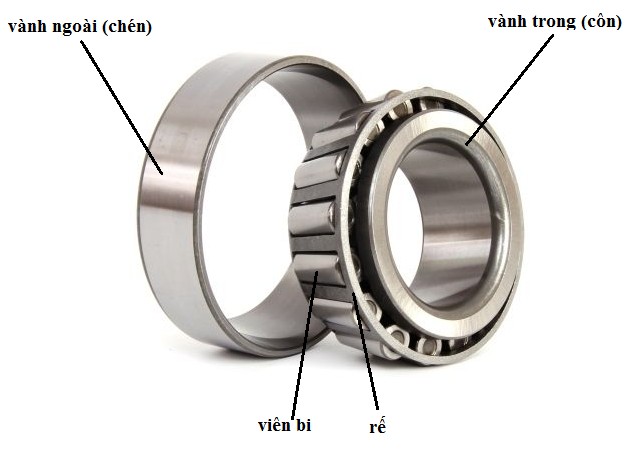

Truck wheel bearing

Truck wheel bearing

Replacing old grease or oil ensures bearings and gears are always optimally lubricated, reducing friction, thereby extending lifespan and ensuring efficient operation. This is a critical step in truck wheel maintenance, helping the vehicle run smoothly and avoiding unnecessary damage.

Truck wheel gears

Truck wheel gears

2. Inspecting Truck Wheel Bearings

After cleaning and lubricating, the next step in truck wheel maintenance is a thorough inspection of the bearings. Early detection of abnormalities such as burning, cracking, or pitting is essential. If any damage is detected, the bearings should be replaced promptly to ensure safe operation. Damaged bearings can cause loud noises, vibrations when the vehicle is moving, and, more seriously, safety hazards while driving.

3. Replacing Truck Wheel Oil Seals

Oil seals prevent dirt and water from entering the bearings while keeping lubricant from leaking out. However, over time and under high temperatures, seals can become hardened, worn, and lose their sealing ability.

Hyundai 15-ton truck wheel oil seal

Hyundai 15-ton truck wheel oil seal

Replacing oil seals is necessary to ensure the wheel system is best protected. New seals will effectively prevent harmful agents, keeping the bearings lubricated and operating smoothly.

4. Inspecting and Maintaining the Truck Wheel Brake System

The brake system is a crucial component directly related to truck driving safety. Inspecting and maintaining the brake system, especially the brake pads, brake shoe springs, and brake shoe pins, cannot be overlooked.

- Brake Pads: If the brake pads are worn, they need to be relined or replaced entirely.

- Brake Shoe Springs: Check the elasticity of the brake shoe springs. If the springs are stretched or weak, they need to be replaced to ensure the brake shoes operate correctly.

- Brake Shoe Pins: If the brake shoe pins are loose with excessive play, the pin bushings need to be reworked to prevent the brake shoes from being misaligned, causing the brakes to not engage or bind.

Truck brake pads

Truck brake pads

Truck brake shoe assembly

Truck brake shoe assembly

Maintaining the brake system ensures effective and safe braking, avoiding dangerous situations while driving.

5. Inspecting Wheel Hubs (for Corrosion), Brake Drums

Wheel hubs and brake drums are subject to high stress and friction during operation. In truck wheel maintenance, the wheel hubs and brake drums need to be inspected for wear, corrosion, or cracking.

Rear wheel hub of a Faw truck

Rear wheel hub of a Faw truck

Worn brake drums will reduce braking efficiency and can even cause the brake drum to shatter during hard braking, which is extremely dangerous. If signs of damage are detected on the wheel hub or brake drum, they should be replaced immediately to ensure safety.

Shacman truck brake drum

Shacman truck brake drum

6. Maintaining and Replacing Wheel Cylinder Cups, Brake Calipers

For hydraulic brake systems, cylinder cups and brake calipers play an important role in transmitting braking force. Inspect and replace cylinder cups and brake calipers if signs of oil leakage are detected.

Truck wheel cylinder cups and brake calipers

Truck wheel cylinder cups and brake calipers

Truck brake caliper

Truck brake caliper

Cylinder cup oil leakage can lead to sudden brake failure, posing a serious hazard. Regular maintenance and replacement of these components is essential.

7. Inspecting Brake Boosters, Foot Brake Valves (Hand Control Valves)

For air brake systems, brake boosters and foot brake valves (hand control valves) need to be inspected. Ensure these components operate smoothly without sticking or air leakage.

Foot brake valve (Hand control valve) of a truck

Foot brake valve (Hand control valve) of a truck

Foot brake valve (Hand control valve) of a truck

Foot brake valve (Hand control valve) of a truck

8. Maintaining Truck Wheel Disc Brakes (If Applicable)

For trucks using disc brakes, the truck wheel maintenance process should include checking the disc brake calipers. If oil leaks are detected from the brake calipers, replace the piston seals to ensure the braking system operates stably.

Truck disc brake caliper

Truck disc brake caliper

Truck disc brake

Truck disc brake

9. Inspecting Truck Wheel Lug Nuts

Truck wheel lug nuts are small components responsible for securing the wheel to the wheel hub. Check the lug nuts for stripped threads or cracks.

Truck wheel lug nuts

Truck wheel lug nuts

Rusty truck wheel lug nuts

Rusty truck wheel lug nuts

Damaged lug nuts can cause loose wheels or even wheel detachment while the vehicle is moving, causing serious accidents. If any problems are detected with the lug nuts, they should be replaced immediately.

Choosing a Reputable Truck Wheel Maintenance Garage

Truck wheel maintenance requires meticulousness, care, and high technical expertise. To ensure your truck is properly maintained, choose reputable and experienced garages.

GARA MINH NHUT is a professional garage in Ho Chi Minh City that provides high-quality truck maintenance and repair services. With a skilled team of technicians and modern equipment, Gara Minh Nhut is committed to providing the best service to customers.

Gara Minh Nhut Contact Information:

- Address: 356 Hoang Huu Nam, Kp. Gian Dan, P. Long Thanh My, Q. 9, TPHCM

- Phone: 0902 915 871 (Mr. Vu)

- Email: [email protected]

- Website: https://garaminhnhut.com/

Contact Gara Minh Nhut now for consultation, service quotes, and to schedule truck wheel maintenance for your vehicle!