Excel, a familiar spreadsheet tool, has been used by many transportation businesses to manage truck maintenance operations. However, is Excel truly the optimal solution for truck maintenance management in the modern context? This article from Xe Tải Mỹ Đình will analyze in detail the pros and cons of managing truck maintenance with Excel, helping you make the most suitable decision for your business.

Advantages of Managing Truck Maintenance with Excel

Familiarity and Ease of Use

The biggest advantage of Excel is its familiarity. Most office staff, especially those in accounting and administration, have experience using Excel. Applying Excel to truck maintenance management does not require extensive training, helping businesses quickly implement and use it. Technical staff can also easily access and become familiar with Excel’s intuitive interface for recording and tracking maintenance work.

Excel for truck maintenance management is still popular in many transport businesses

Excel for truck maintenance management is still popular in many transport businesses

Ubiquity and Low Cost

Excel is a common software, often pre-installed on most office computers. This helps businesses save on software investment costs, as well as avoid additional usage license fees. In addition, sharing and exchanging Excel files between departments is very easy, facilitating work coordination. For small businesses, startups, or those with limited budgets, managing truck maintenance with Excel is an economical and accessible option.

Serious Disadvantages of Managing Truck Maintenance with Excel

Despite certain advantages, managing truck maintenance with Excel also has significant disadvantages, especially as transportation businesses grow and fleet sizes increase.

Difficulty in Controlling Large and Complex Data

Excel can struggle to manage large and complex data related to truck fleet maintenance. With a large number of trucks, extensive maintenance history, and diverse parts catalogs, data entry, tracking, and retrieval in Excel become slow and prone to errors. Managing detailed information about each vehicle, periodic maintenance schedules, repair history, incurred costs, and the status of replacement parts becomes cumbersome and difficult to control.

Data Security Risks

The data security of managing truck maintenance with Excel is also a significant concern. Excel files can be easily copied, edited, or deleted by anyone with access. This can lead to the loss of important data, leakage of information about vehicle status, maintenance history, and costs, affecting business operations and internal information security of the enterprise.

Limited Ability for Aggregation and Reporting

Excel has basic data aggregation and reporting capabilities, but it is limited when in-depth analysis and specialized reports on truck maintenance activities are needed. Creating overview reports on maintenance costs by vehicle type, statistics on the frequency of component failures, analyzing the effectiveness of periodic maintenance, or tracking parts lifecycles becomes complex and time-consuming. This makes it difficult to make effective maintenance management decisions and optimize costs.

More Effective Excel Alternatives for Truck Maintenance Management

To overcome the disadvantages of managing truck maintenance with Excel, transportation businesses should consider switching to professional maintenance management software (CMMS – Computerized Maintenance Management System). CMMS software is specifically designed to comprehensively manage maintenance operations, including:

- Asset Management: Storing detailed information about each truck, part, and equipment.

- Maintenance Planning: Scheduling periodic maintenance and preventive maintenance.

- Maintenance History Management: Recording the entire repair and maintenance history of each vehicle.

- Spare Parts Inventory Management: Tracking the quantity, location, and status of spare parts.

- Reporting and Analytics: Creating diverse reports on costs, maintenance effectiveness, and vehicle status.

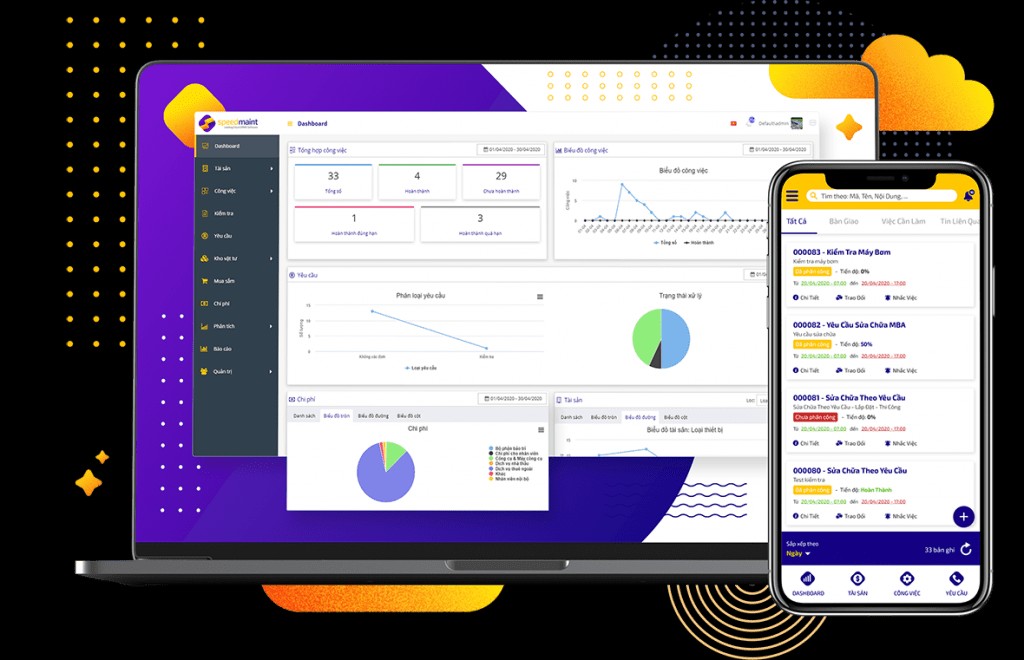

CMMS SpeedMaint truck maintenance management software is an effective Excel alternative

CMMS SpeedMaint truck maintenance management software is an effective Excel alternative

CMMS software helps businesses manage truck maintenance scientifically and efficiently, minimizing errors, saving time and costs, while improving the lifespan and operational efficiency of the fleet.

Conclusion:

Managing truck maintenance with Excel can be a temporary solution for small-scale transportation businesses with a small fleet and simple operations. However, as businesses grow and fleet sizes increase, the disadvantages of Excel will become increasingly apparent. Switching to professional CMMS software is a necessary step to improve maintenance management efficiency, optimize costs, and ensure stable and sustainable transportation operations. Carefully consider and choose the maintenance management solution that best suits your business needs and scale.