As a content creator at Xe Tải Mỹ Đình, I understand that choosing the right material for a truck body is a crucial decision that directly impacts the durability, load capacity, and operating costs of the vehicle. Among these materials, stainless steel (Inox) is a popular choice due to its rust resistance and aesthetic appeal. However, not everyone is familiar with the different types of stainless steel and how to distinguish between them, especially when researching information in English. This article will help you differentiate truck types in English while delving deeper into the types of stainless steel commonly used for truck bodies, assisting you in making the most optimal choice.

Shiny stainless steel material, commonly used in truck body manufacturing, showcasing aesthetics and durability.

Shiny stainless steel material, commonly used in truck body manufacturing, showcasing aesthetics and durability.

Stainless steel, also known as Inox, is a renowned alloy celebrated for its exceptional corrosion resistance. The term “Inox” originates from “Inoxydable” in French and “Inoxidizable” in English, both meaning “non-oxidizing.” This very characteristic makes stainless steel an ideal material for numerous applications, from household appliances and industry to the transportation sector, particularly in truck body construction.

Before stainless steel emerged, steel and aluminum were prevalent materials in equipment manufacturing. However, they were susceptible to oxidation, especially in humid environments. In 1913, British metallurgist Harry Brearley invented stainless steel by adding Chromium, Nickel, and Manganese and reducing the Carbon content in steel, sparking a revolution in the materials industry. The proportions of these elements determine the type of stainless steel and its properties. Common stainless steel types today include 304, 201, 202, 430, and 316, each offering unique advantages and applications.

Stainless Steel Grades Commonly Used in Truck Body Construction

In the Vietnamese market, three stainless steel grades are most trusted by truck body manufacturers: Inox 430, Inox 201, and Inox 304. Let’s explore each type in detail:

Inox 430: Economical Choice for Dry Cargo Truck Bodies

The most recognizable characteristic of Inox 430 is its magnetic property. You can easily test it with a magnet; if the magnet strongly adheres, it is Inox 430. Among household stainless steel grades, Inox 430 has the lowest quality and cost. The durability and corrosion resistance of Inox 430 are moderate, resulting in a generally shorter product lifespan. However, priced at only 3/4 of Inox 201 and 1/2 of Inox 304, Inox 430 remains an economical option for many applications.

Inox 430 is suitable for constructing truck bodies for dry cargo, with minimal exposure to corrosive environments. Its resistance to fresh water and rain is quite good. Compared to steel, truck bodies made of Inox 430 offer a more aesthetic and polished appearance. At Xe Tải Mỹ Đình, we often use Inox 430 for standard truck bodies, especially for light-duty trucks or flatbed trucks, ensuring both durability and a visually appealing look for the vehicle over time. In English, these types of trucks can be referred to as light-duty trucks or flatbed trucks.

Truck body made of Inox 430, featuring a shiny, aesthetic surface, suitable for transporting general goods.

Truck body made of Inox 430, featuring a shiny, aesthetic surface, suitable for transporting general goods.

Inox 430 has a shiny surface, but it’s important to note that this type of stainless steel is susceptible to strong corrosive substances.

Inox 201: Balancing Quality and Cost

Inox 201 is non-magnetic (approximately 90%) and has good durability. However, direct contact with acids or salts should be avoided. In truck body construction, Inox 201 is commonly used for components like side panels, side guards, or body frames. Inox 201 box sections are popular in sizes 4×4, 4×8, or 2×2.

Inox 201 offers a balance between quality and cost, making it suitable for various truck body types, particularly box trucks or curtain-side trucks. In English, these are called box trucks or curtain-side trucks. With better durability and rust resistance than Inox 430, Inox 201 ensures the longevity and aesthetics of the truck body while maintaining a reasonable cost.

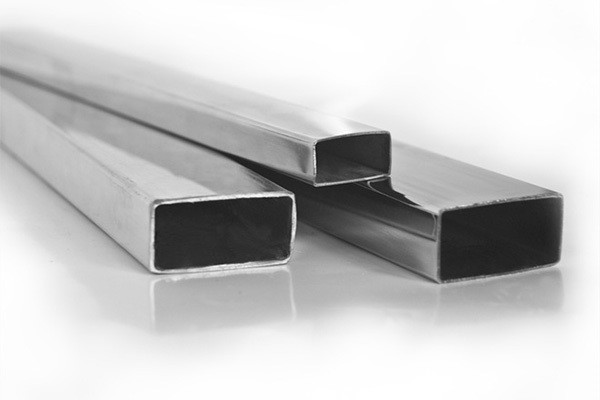

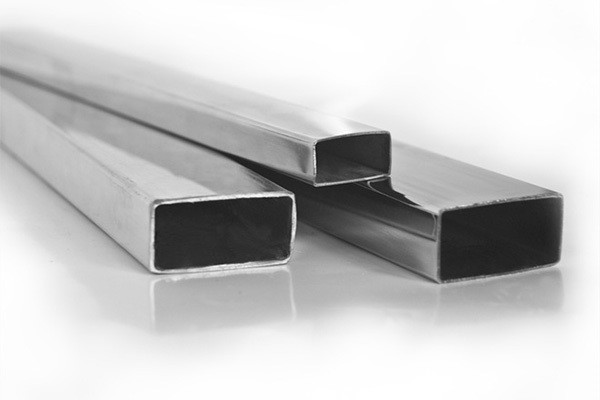

Detailed image of a truck body with the frame and side panels made of Inox 201, showcasing robustness and load-bearing capacity.

Detailed image of a truck body with the frame and side panels made of Inox 201, showcasing robustness and load-bearing capacity.

Inox 304: Premium Material for Specialized Truck Bodies

Inox 304 is a non-magnetic stainless steel grade suitable for all environments, maintaining its shine and being particularly food-safe. Inox 304 boasts superior advantages such as extremely high durability, ease of thinning, and excellent corrosion resistance compared to other stainless steel grades. However, Inox 304 is also the most expensive among stainless steel types.

Inox 304 is the top choice for constructing specialized truck bodies like seafood trucks (English: refrigerated trucks or fish trucks), chemical tankers (English: chemical tankers), or vehicles for highly corrosive goods. With its resistance to harsh environments and chemicals, Inox 304 ensures maximum safety and durability for the truck body, protecting cargo and extending vehicle lifespan. Despite a higher initial investment, Inox 304 offers long-term economic efficiency due to its superior durability and protection.

| Feature | Inox 304 | Inox 201 | Inox 430 |

|---|---|---|---|

| Composition | 18% Chromium, 10% Nickel, balance Iron and other elements. | 18% Chromium, 3% Nickel, balance Iron and other elements. | 18% Chromium, 0% Nickel, balance Iron and other elements. |

| Pros & Cons | Shiny but slightly cloudy. Clean, rust-free, durable. Feels heavy. | Shiny appearance like Inox 304 but lower Nickel content, lighter, prone to corrosion, surface pitting. | High iron and impurities. Initially shiny but dulls over time. Rusts easily in contact with water and seasonings, low durability, not safe. Feels light. |

| Testing Methods | – Non-magnetic or slightly magnetic. – Scratch the surface, apply toilet bowl cleaner, minimal change after 15-20 minutes. – Turns gray with acid test. | – Difficult to distinguish from Inox 304 visually. – Non-magnetic or slightly magnetic. – Turns yellowish-brown with toilet bowl cleaner test. – Turns brick red with acid test. | Strongly magnetic, attracts even when brought near. Strong magnetic pull in hand. |

| Induction Cooktop Use | No. | No. | Yes. |

| Applications | Knives, spoons, forks, stoves, pots, pans. | Stoves, pans, pots, interior and exterior decoration. | Items with minimal water contact. |

| Price | High. | Medium. | Low. |

Stainless Steel Truck Body Construction Services at Xe Tải Mỹ Đình

When purchasing a truck and having its body built at Xe Tải Mỹ Đình, customers will experience professional and dedicated service:

- Workshop Tour: Customers are welcome to visit our modern truck body building factory, witnessing firsthand the stainless steel materials and production process.

- Quality Commitment: We guarantee that truck bodies are built to the correct dimensions and with the specified type of stainless steel as per the contract.

- Genuine Warranty: Truck bodies are covered by a genuine warranty at Xe Tải Mỹ Đình for 1 year, with unlimited mileage.

- Genuine Parts: We use genuine parts and accessories, ensuring the durability and safety of the vehicle.

- Financial Support: Consultation and support for financing up to 70% – 80% of the vehicle and body value, flexible loan terms from 3-7 years, preferential interest rates. Quick procedures and enthusiastic staff.

- Turnkey Service: Assistance with registration, inspection, and completion of “turnkey” procedures.

To receive detailed advice and choose the most suitable stainless steel grade for your truck body based on your transportation needs, please contact Xe Tải Mỹ Đình immediately via phone at 09xxxxxxxxx or visit the website xetaimydinh.com for more information.

With this article, we hope you have gained a comprehensive and detailed understanding of the stainless steel grades commonly used for truck bodies, as well as a clearer understanding of how to differentiate truck types in English through the application of stainless steel materials in each specialized vehicle. Xe Tải Mỹ Đình is always ready to accompany you on every journey.