Leaf springs are a crucial part of a truck’s suspension, absorbing road impacts, reducing shocks, and ensuring stability. The size of the leaf spring directly affects load capacity and shock absorption. This article analyzes the role of leaf springs, common types, and signs of maintenance needs.

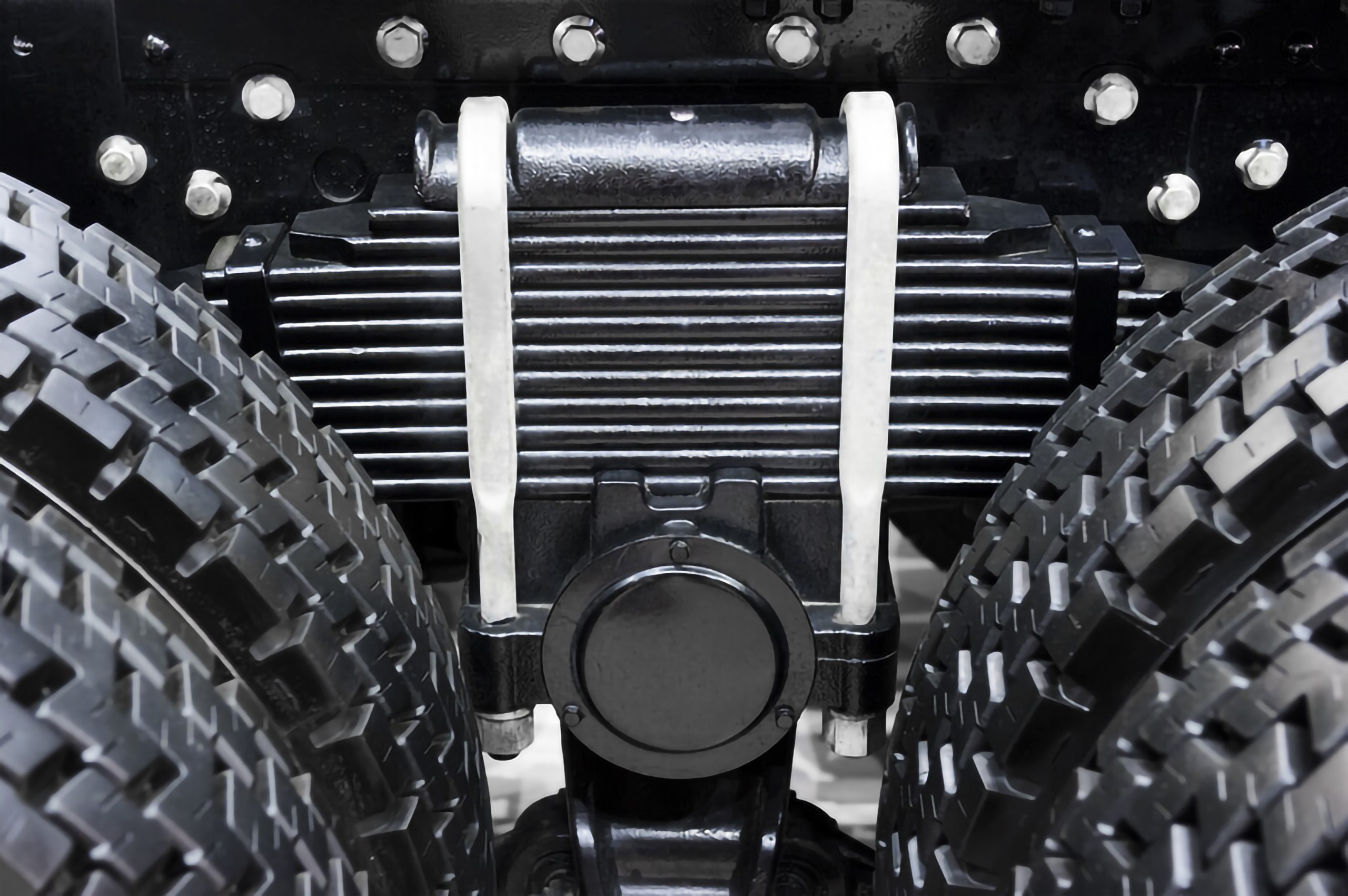

Image: Truck leaf spring, part of the suspension system, primarily absorbs shocks for smooth vehicle operation.

Image: Truck leaf spring, part of the suspension system, primarily absorbs shocks for smooth vehicle operation.

The Role of Leaf Spring Size in Truck Suspension

Truck leaf springs, also known as laminated springs, are a collection of elastic steel leaves stacked on top of each other, increasing in length from the inside out. The size of the leaf spring, including length, width, and thickness, is carefully calculated to suit the load and operating characteristics of each type of vehicle. Larger leaf spring sizes allow for higher load capacities. Conversely, smaller leaf springs are better suited for light trucks, helping them run more smoothly on flat roads.

Classification of Truck Leaf Springs by Size and Structure

There are many types of truck leaf springs on the market today with different sizes and structures, meeting the diverse needs of users. Here are some common types of leaf springs:

Multi-Leaf Springs

This is a traditional type of leaf spring, constructed from multiple steel leaves stacked on top of each other. Truck leaf spring sizes of this type are diverse, suitable for many types of trucks from small to large. The advantages of multi-leaf springs are that they are inexpensive, easy to repair and maintain.

Image: Multi-leaf springs are inexpensive, easy to repair and maintain.

Image: Multi-leaf springs are inexpensive, easy to repair and maintain.

Parabolic Leaf Springs

Parabolic leaf springs have a more modern design, with steel leaves in a parabolic shape. This type of spring has better shock absorption than traditional multi-leaf springs, is less prone to warping, and has high durability. However, parabolic springs are more expensive and more complicated to repair.

Elliptical Leaf Springs

Elliptical springs are constructed from an elastic steel rod in an elliptical shape. The advantages of elliptical springs are that they are compact, provide good shock absorption, and are less prone to deformation. However, this type of spring is expensive and difficult to repair.

Air Leaf Springs

Air leaf springs use an elastic steel air spring to absorb shocks. This is the type of spring with the best shock absorption among truck leaf springs. However, air leaf springs are bulky and difficult to repair.

Signs of Truck Leaf Springs Requiring Maintenance

Recognizing early signs of leaf spring damage will help you promptly maintain or replace them, avoiding affecting the operating performance and safety of the vehicle. Some signs to look out for include:

- The vehicle shakes violently when moving on rough roads.

- Strange noises appear from the suspension system.

- The leaf spring is bent, cracked, or broken.

- The vehicle veers off course when moving.

- The tires wear unevenly.

- The vehicle is lowered lower than normal.

Image: It is important to recognize the signs of truck leaf springs needing maintenance.

Image: It is important to recognize the signs of truck leaf springs needing maintenance.

Conclusion

Truck leaf spring size is an important factor affecting the load capacity and shock absorption of the vehicle. Choosing the right type of leaf spring and periodic maintenance will help the vehicle operate stably, safely and extend its life. When any signs of damage are detected, take the vehicle to reputable maintenance centers for inspection and timely handling.