Truck jacks are essential tools for drivers, providing a safe and easy way to lift trucks for repairs, maintenance, or roadside emergencies. This article offers an overview of various truck jack types, along with guidance on selecting and using them safely and effectively.

Hydraulic jack is essential for lifting cars

Hydraulic jack is essential for lifting cars

What is a Truck Jack?

A truck jack, also known as a vehicle jack, is a mechanical device used to lift a truck off the ground. This creates space under the vehicle for maintenance, repairs, or component replacements, such as tires, suspension, or brakes. Truck jacks are designed to be durable and handle the heavy loads of trucks.

Types of Truck Jacks

1. Hydraulic Jacks

Hydraulic jack

Hydraulic jack

- Structure: Includes a hydraulic oil reservoir, piston, check valve, pump handle, release valve, lifting arm, and base.

- Operating Principle: Based on Pascal’s principle, the hydraulic oil pressure generated by the pump handle pushes the piston up, raising the lifting arm and the vehicle. The release valve lowers the vehicle.

- Advantages: Affordable, compact, easy to move, requires no electricity, and can lift heavy loads.

- Disadvantages: Slow lifting speed, requires manual pumping, and may not be highly durable.

- Types: Bottle jacks (for tire changes), floor jacks (for undercarriage repairs), and trolley jacks (for stable lifting).

2. Electric Jacks

Electric jack

Electric jack

- Structure: Includes an electric motor, gearbox, lead screw, lifting arm, control switch, and power cord.

- Operating Principle: The electric motor rotates, moving the lead screw, which raises the lifting arm to lift the vehicle. Turning off the motor lowers the vehicle by gravity.

- Advantages: Fast lifting and lowering, requires no manual effort, can be remotely controlled, and includes safety features.

- Disadvantages: Expensive, requires a power source to operate.

3. Air Jacks

Air jack

Air jack

- Structure: Includes the jack body, airbag, control valve, air hose, and quick connector.

- Operating Principle: Compressed air is pumped into the airbag, causing it to inflate and lift the vehicle. Releasing the air deflates the airbag, lowering the vehicle.

- Advantages: Extremely fast lifting, high load capacity, suitable for professional garages.

- Disadvantages: Bulky, difficult to move, requires an air compressor, and expensive.

4. Mechanical Jacks (Scissor Jacks)

Scissor jack

Scissor jack

- Structure: Two metal arms forming an “A” shape, a lead screw, and a hand crank.

- Operating Principle: Turning the hand crank moves the lead screw, pushing the metal arms apart, lifting the vehicle.

- Advantages: Simple design, easy to use, affordable.

- Disadvantages: Limited lifting capacity, requires significant manual effort.

Choosing the Right Truck Jack

Choosing the right jack for your needs

Choosing the right jack for your needs

When selecting a truck jack, consider these factors:

- Lifting Capacity: Must exceed the weight of the truck.

- Lifting Height: Sufficient for comfortable work under the vehicle.

- Material: Stainless steel or aluminum alloy.

- Brand: Reputable, high-quality, with a comprehensive warranty.

- Price: Suitable for your budget and usage needs.

For trucks: Choose a hydraulic trolley jack or an air jack with a high load capacity (3 tons or more).

Safe Truck Jack Usage

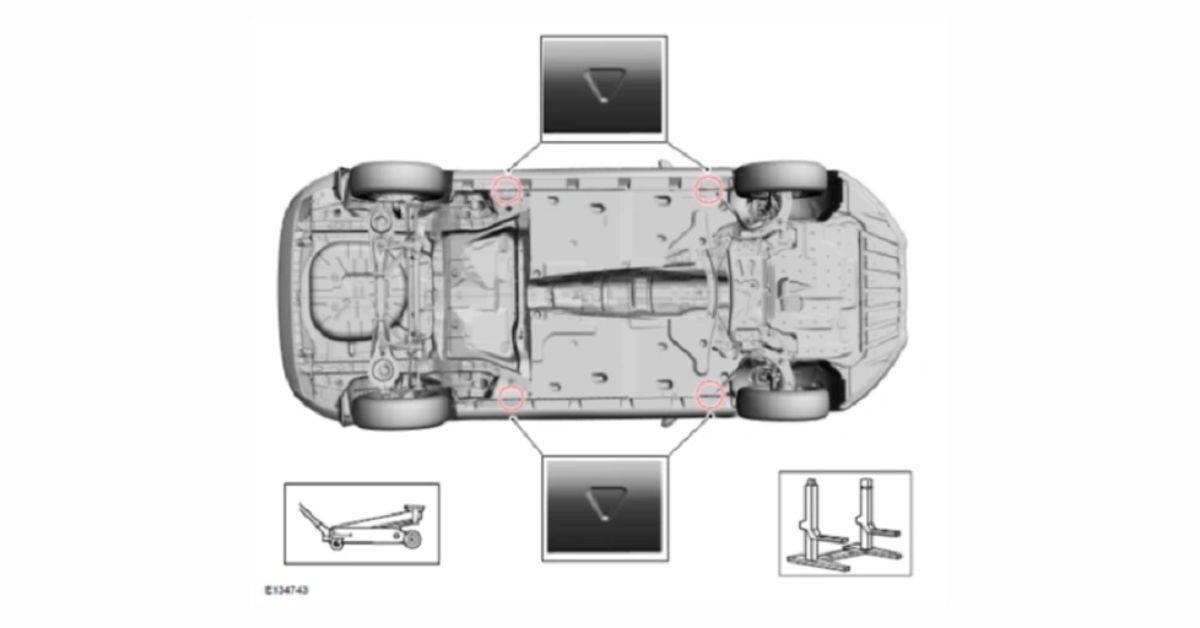

Car jack placement points

Car jack placement points

- Identify the Lifting Points: Locate the designated lifting points on the vehicle’s frame near the wheels.

- Place the Jack on a Flat, Solid Surface: Avoid soft ground, sand, or gravel.

- Use Wheel Chocks: Place chocks on the wheels opposite the one being lifted.

- Lift the Vehicle Slowly and Steadily: Ensure the vehicle is lifted evenly and does not tilt.

- Use Jack Stands: Place jack stands or sturdy supports to support the vehicle when working underneath.

- Never work under a vehicle supported only by a jack.

Truck Jack Maintenance

Maintaining your car jack for longevity

Maintaining your car jack for longevity

- Cleaning: Wipe clean after each use.

- Lubrication: Periodically lubricate moving parts.

- Component Inspection: Check the base, handle, release valve, seals, etc.

- Timely Repairs: Address any sticking, oil leaks, or other damage promptly.

A truck jack is a critical tool for every driver. Choosing the right type, using it correctly, and maintaining it properly will ensure safety and efficiency.