Truck leaf springs are a crucial part of the suspension system, absorbing road impact, reducing shocks, and ensuring smooth vehicle operation. Understanding their structure, operation, and maintenance helps you choose the right components and maintain your truck’s stability.

Truck leaf spring assembly with multiple steel leaves stacked together

Truck leaf spring assembly with multiple steel leaves stacked together

Truck Leaf Spring Structure

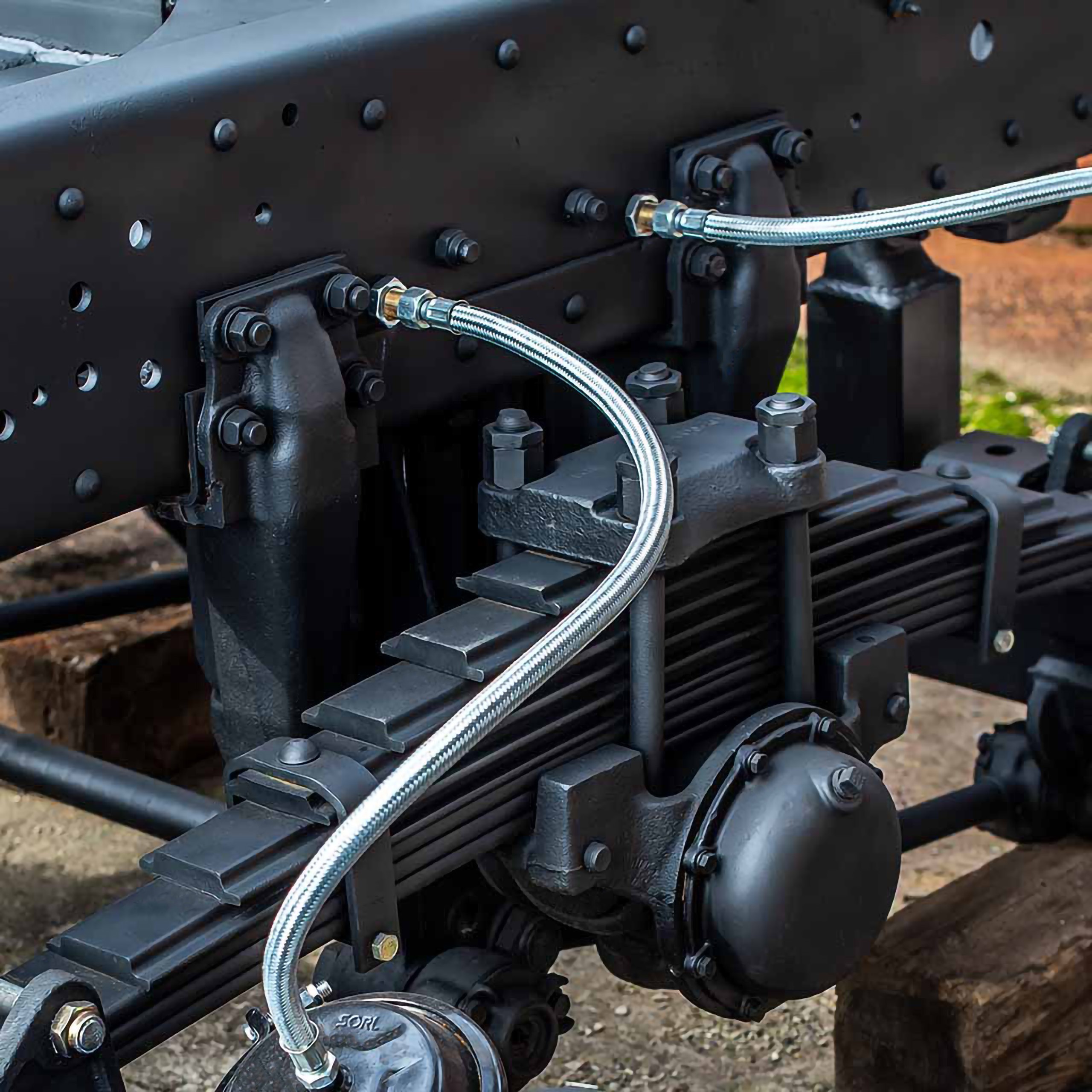

A truck leaf spring is composed of elastic steel leaves stacked in order from shortest to longest, forming a unified unit. The more leaves, the greater the load capacity. Key components include:

- Leaf springs: Made of high-elastic steel, varying in size and stacked with a certain curvature.

- Leaf spring pads: Made of plastic or metal to reduce friction between the leaves.

- Leaf spring bolts: Secure the leaves and pads to the vehicle frame.

- Shackles: Connect the leaf spring to the frame and axle.

- Shock absorbers: Dampen vibrations transmitted from the springs to the frame.

Truck Leaf Spring Types

Several types of truck leaf springs exist, each with its own advantages and disadvantages:

Leaf Springs

The most common type, consisting of multiple stacked elastic steel leaves. Advantages: affordable, easy to repair and maintain. Disadvantages: poorer shock absorption compared to other types.

Coil Springs

Made of a cylindrical elastic steel bar. Advantages: compact, good shock absorption, less prone to warping. Disadvantages: expensive, difficult to repair.

Air Springs

Made of an elastic air-filled bellow. Advantages: best shock absorption. Disadvantages: bulky, difficult to repair.

Parabolic Springs

Made of multiple parabolic-shaped elastic steel leaves. Advantages: smooth shock absorption, less warping, high durability. Disadvantages: expensive, difficult to repair.

Close-up of parabolic leaf springs on a truck, showing the parabolic shape of the leaves

Close-up of parabolic leaf springs on a truck, showing the parabolic shape of the leaves

Operating Principle

Leaf springs operate based on the elasticity of steel. When the vehicle travels over uneven roads, force is transmitted to the leaf spring, causing the steel leaves to bend. Due to their elasticity, the leaves return to their original position after absorbing the force, reducing shock and vibration.

Diagram illustrating how leaf springs compress and rebound when a truck encounters a bump

Diagram illustrating how leaf springs compress and rebound when a truck encounters a bump

Signs Your Truck Leaf Springs Need Maintenance

- Excessive shaking when driving on rough roads.

- Strange noises from the leaf springs.

- Bent, cracked, or broken leaves.

- Vehicle veering off course.

- Uneven tire wear.

- Vehicle sitting lower than normal.

A close-up shot of a damaged and rusty leaf spring on a truck

A close-up shot of a damaged and rusty leaf spring on a truck

Truck Leaf Spring Maintenance Procedure

- Prepare tools: Pliers, wrenches, socket set, hammer, brush, lubricating oil, rags, leaf spring pads.

- Inspection: Inspect leaf spring components for bending, cracks, breaks, looseness, or rust.

- Cleaning: Remove dirt and debris from the leaf spring.

- Lubrication: Lubricate the leaves, bolts, nuts, and rubber pads with appropriate lubricating oil.

- Reassembly: Reassemble components in their original positions, tightening bolts to the correct torque.

Mechanic lubricating the leaf springs of a truck during a maintenance check

Mechanic lubricating the leaf springs of a truck during a maintenance check

Conclusion

Truck leaf springs play a vital role in ensuring smooth and safe operation. Regular and proper maintenance extends the lifespan of the leaf springs and ensures optimal vehicle performance. Contact Xe Tải Mỹ Đình for consultation and support on all matters related to truck leaf springs.