Truck air suspensions are vital for smooth and stable operation, especially when hauling heavy loads. This article by Xe Tai My Dinh offers an overview of truck air suspensions, covering their structure, function, failure signs, and replacement process.

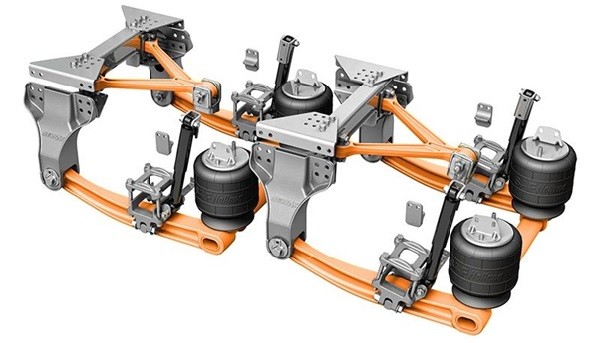

Truck air suspension structure

Truck air suspension structure

What is a Truck Air Suspension?

A truck air suspension, also known as an air ride system, uses compressed air to support the vehicle’s weight. Instead of traditional leaf springs, air suspensions utilize airbags made from high-quality rubber, offering excellent elasticity and pressure resistance. The system operates with a controller and a pump powered by electricity or an air compressor.

Benefits of Truck Air Suspension

Truck air suspensions provide several significant advantages:

Smooth and Stable Ride

Air suspensions absorb vibrations better than leaf springs, resulting in a smoother ride, particularly on rough roads. This enhances driver comfort and protects cargo from impacts.

Air suspension improves truck ride comfort

Air suspension improves truck ride comfort

Extends Tire Life

Air suspensions reduce the force transmitted from the wheels to the vehicle body, lessening the load on the tires and promoting even wear, extending their lifespan.

Reduces Noise

Compared to leaf springs, air suspensions significantly reduce noise, creating a quieter working environment for the driver.

Adjustable Ride Height

Drivers can adjust the vehicle’s ride height according to road conditions and cargo load, facilitating easier maneuvering.

Air suspension reduces leaf spring arch

Air suspension reduces leaf spring arch

Increases Load Capacity

Air suspensions allow trucks to carry heavier loads while maintaining safety and stability.

Signs You Need to Replace Your Truck Air Suspension

When your truck’s air suspension malfunctions, you may notice the following signs:

- Excessive shaking while driving.

- The vehicle leans to one side.

- Difficult handling, steering wheel pulls.

- Uneven tire wear.

- The air compressor runs constantly or shuts off abruptly.

Air suspension reduces load on the truck

Air suspension reduces load on the truck

Truck Air Suspension Replacement Process

Replacing a truck air suspension requires specialized expertise. The replacement process typically involves these basic steps:

- Disconnect Power: Ensure safety by disconnecting the vehicle’s power supply.

- Lift the Vehicle: Use a lift to raise the vehicle, creating space for work underneath.

- Inspect Air System: Examine the entire air system, including air lines, control valves, and the compressor.

- Remove Old Air Suspension: Disconnect the air lines and bolts securing the air suspension.

- Install New Air Suspension: Install the new air suspension according to proper technical procedures.

- Re-inspect System: After installation, re-inspect the entire system, ensuring there are no air leaks and the system is functioning correctly.

Proper installation of air suspension is necessary

Proper installation of air suspension is necessary

Conclusion

Truck air suspensions are a crucial component, contributing to enhanced vehicle performance and safety. Regular maintenance and replacement of the air suspension are necessary to ensure optimal vehicle operation. Contact Xe Tai My Dinh for consultation and support regarding truck air suspensions. We offer professional air suspension inspection, maintenance, and replacement services, guaranteeing quality and reliability.