Truck horns are essential for signaling and safety. However, misuse, especially loud horns, can cause disturbance and legal issues. This article from Xe Tải Mỹ Đình provides detailed information on current regulations and penalties for loud truck horns, helping drivers comply with the law and promote safe driving.

I. Types of Truck Horns According to Regulations

Truck horns are part of the vehicle’s sound system, used for warning and assistance. The two main types are air horns and electric horns.

- Air Horns: Commonly found on heavy-duty trucks, tractor-trailers, and containers with pneumatic systems for braking and other functions. Air horns are loud and far-reaching, suitable for noisy highway environments.

Air horn commonly installed on large trucks

Air horn commonly installed on large trucks

- Electric Horns: More common on small and light trucks and cars. Electric horns are simple, easy to install and maintain, and have moderate volume, suitable for urban traffic.

Electric horn design:

- Electric horn circuit: Includes horn button, ignition switch, electric horn, horn relay, and battery.

- Operating principle: Pressing the horn button closes the relay, powering the horn and producing sound. Releasing the button disconnects power, stopping the horn.

- Electric horn structure: Consists of a shell, electromagnet, capacitor, contact point, control post, magnetic steel plate, vibrating disc, vibrating membrane, and sound adjustment mechanism.

Most new trucks come with 2-3 electric horns. Unauthorized modifications or custom horns are violations and can result in penalties.

Trucks are often equipped with 2-3 electric horns

Trucks are often equipped with 2-3 electric horns

II. Proper Truck Horn Usage Regulations

The 2008 Road Traffic Law and related legal documents specify the use of horns while driving. Drivers must strictly adhere to these regulations to ensure safety and avoid fines. Key regulations include:

- Limit horn use in urban and residential areas: Especially from 10 PM to 5 AM, except for emergency vehicles, minimize horn use in urban and populated areas.

- Do not use air horns in urban and residential areas: This is crucial. Air horns are loud and can startle people, especially at night.

- Ensure the horn works: Vehicles must have a functioning horn. Do not remove the horn.

- Use standard horns: The horn must meet the standards for the vehicle type; do not modify or install inappropriate horns.

- Use horns only when necessary: The main purpose of the horn is to warn of danger or request the right of way in necessary situations. Avoid unnecessary horn use to prevent noise pollution and disturbance.

Using the horn correctly helps drivers avoid fines and demonstrates traffic etiquette, contributing to a safe and civilized traffic environment.

Honking properly reflects good driving etiquette

Honking properly reflects good driving etiquette

III. Truck Electric Horn Volume Regulations and Inspection Standards

According to Appendix 1 of Circular 10/2009/TT-BGTVT on “Technical Safety Inspection and Environmental Protection of Road Motor Vehicles,” the volume of electric truck horns must meet certain standards.

The standard volume for car and truck horns must be between 90dB(A) and 115dB(A). Sounds below 90dB(A) or above 115dB(A) are non-compliant. The horn sound must be stable, continuous, and free of interruptions, buzzing, or distortion.

Horn volume testing procedure:

To test the horn volume, use a specialized sound level meter and follow these steps:

Step 1: Place the microphone 2 meters from the front of the vehicle, 1.2 meters above the ground, centered and facing the vehicle.

Step 2: Sound the horn and record the volume displayed on the meter.

If the measured volume is between 90dB(A) and 115dB(A), the horn meets the volume standard.

Checking truck horn volume with a sound level meter

Checking truck horn volume with a sound level meter

IV. Common Truck Horn Problems and Solutions

During use, truck horns may experience some issues. Here are the 4 most common problems and how to fix them:

1. Intermittent Truck Horn

An intermittent horn often occurs when the vehicle travels over rough roads. This can be caused by poor horn button contact, loose control wires, or unstable relay operation. The horn terminals may also oxidize over time, reducing contact.

Solution:

Clean the contact points of the horn button and horn terminals. Check and tighten the wiring connections. If necessary, replace the horn relay.

Cleaning the contact points of a truck horn

Cleaning the contact points of a truck horn

2. Horn Does Not Sound at All

This is a serious issue that can cause danger since the vehicle cannot alert others. The cause may be a faulty horn button, relay, weak or dead battery, or loss of ground connection at the horn.

Solution:

Step 1: Clean and scrape the horn’s ground points, ensuring good contact. Consider adding a ground wire to the horn system.

Step 2: Check the battery and relay. Use a test light to check the power supply to the horn. If there is no power, check the circuit from the battery to the horn. If there is power, continue checking the relay.

Step 3: If the relay is good, check the circuit from the relay to the horn. If the circuit is good, the horn may be faulty and needs replacement.

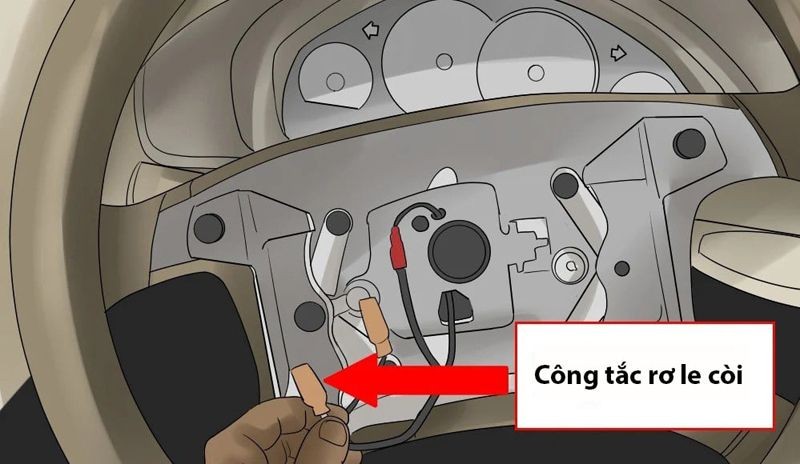

Checking the relay and battery when the horn does not sound

Checking the relay and battery when the horn does not sound

3. Horn Sounds Too Quiet

A quiet horn may be due to one or more faulty horns in the system, or the horn is dirty, has poor contact with the power supply, or is partially damaged.

Solution:

Clean the horn. Check the power supply to the horn. If necessary, replace the faulty horn. Horns typically have a lifespan of 3-5 years, so check and replace them regularly.

Quiet horn can be caused by several factors

Quiet horn can be caused by several factors

4. Horn Sounds Continuously

The cause may be a stuck horn button, a faulty horn relay, or a short circuit in the wiring from the relay to the horn button.

Solution:

Step 1: Check if any horn components are burned out.

Step 2: If the coil is broken or burned, rewind or replace it. If the contacts are burned or have poor contact, clean the contacts. Check and replace the spring if its elasticity is reduced.

Checking the horn relay when the horn sounds continuously

Checking the horn relay when the horn sounds continuously

V. Instructions for Replacing a Damaged Truck Horn

Replacing a truck horn is not too complicated, but it must be done correctly to ensure safety and effectiveness.

Step 1: Identify the exact cause of the horn’s malfunction. If the horn is damaged, proceed with replacement.

Step 2: Remove the old horn:

- Locate the horn (usually on the radiator support or behind the grille).

- Disconnect the battery.

- Disconnect the horn’s electrical connector by pressing down and sliding it out.

- Remove the horn’s mounting bolts.

- Remove the old horn.

Removing an old truck horn

Removing an old truck horn

Step 3: Install the new horn:

- Place the new horn in the old position.

- Reinstall the mounting bolts, tightening them sufficiently.

- Plug the electrical connector into the new horn (horns have positive and negative terminals).

- Connect the negative terminal to a bolt on the chassis, and the positive terminal to the power supply.

- Reconnect the battery.

Step 4: Test the new horn by sounding it.

Note: The replacement process may vary depending on the specific make and model of the vehicle. If you are not confident, take the vehicle to a professional garage for assistance.

Installing a new truck horn

Installing a new truck horn

VI. Tips to Keep Truck Horns Working Well and Lasting Long

To keep truck horns working well and lasting long, note the following:

1. Limit Water Entry into the Horn

Water entering the horn can cause rust, affecting the sound and lifespan of the horn. Minimize water intrusion, especially when washing the vehicle or driving in bad weather.

Limit water from entering the truck horn

Limit water from entering the truck horn

2. Clean and Maintain Horns Regularly

Cleaning and maintaining the horn regularly helps it operate stably and last longer. Avoid using hard, sharp objects to poke inside the horn, especially snail horns, as this can damage the vibrating membrane and waterproof membrane. Clean the horn mounting area to ensure good ground contact; consider adding a ground wire to the horn.

Clean the truck horn regularly

Clean the truck horn regularly

3. Do Not Connect Horns Yourself

Improper horn connection can cause a fire in the vehicle’s electrical system and affect the horn’s sound. If you are not familiar with automotive electrical systems, it is best to take the vehicle to a professional garage or service center for assistance.

Do not install the truck horn at home

Do not install the truck horn at home

VII. How to Adjust Truck Horn Volume

If you feel the truck horn volume is not suitable, you can adjust it yourself at home. The horn sound depends on the frequency and amplitude of the horn membrane, which often change when adjusting the gap between the two contacts. In addition, the tension of the leaf spring and the gap between the steel core and steel frame also affect the opening and closing of the contacts.

To adjust the volume, you can turn the adjustment screw on the horn, while adjusting the tension of the leaf spring and the gap between the steel core and the steel frame to change the frequency and amplitude, thereby changing the loudness of the horn. If you cannot adjust it yourself, go to an auto repair center for assistance.

Adjusting truck horn volume

Adjusting truck horn volume

VIII. Prohibited Acts When Using Truck Horns and Specific Fines

The 2008 Road Traffic Law and Decree 100/2019/ND-CP clearly stipulate prohibited acts when using car horns and corresponding fines. Understanding and complying with these regulations is crucial.

Prohibited acts and fines:

| Act | Fine | Legal Basis |

|---|---|---|

| Operating a car with a horn that exceeds the prescribed volume. | Fine of 2,000,000 – 3,000,000 VND, confiscation of horn. | Point d, Clause 4; and Point b, Clause 6, Article 16 |

| Sounding the horn in crowded residential areas from 10 PM to 5 AM (except for emergency vehicles). | Fine of 200,000 – 400,000 VND. | Point g, Clause 1, Article 5 |

| Operating a vehicle without a horn or with a non-functional horn. | Fine of 300,000 – 400,000 VND, forced to install full equipment. | Point b, Clause 2, and Point a, Clause 7, Article 16 |

| Sounding the horn continuously, revving the engine, sounding air horns in urban or crowded residential areas (except for emergency vehicles). | Fine of 800,000 – 1,000,000 VND. | Point b, Clause 3, and Point c, Clause 11, Article 5 |

Therefore, the answer to the question “how much is the fine for a loud truck horn?” is that the fine for “operating a car with a horn that exceeds the prescribed volume” is from 2,000,000 to 3,000,000 VND, with confiscation of the violating horn.

In addition, installing and using improper horns such as air horns, musical horns, or imitation horns is a violation and can be penalized. More seriously, if the improper use of the horn causes a fatal traffic accident, the offender may be prosecuted under Article 128 of the 2015 Penal Code, amended and supplemented in 2017, regarding the crime of unintentional manslaughter.

Improper horn use results in a fine

Improper horn use results in a fine

IX. How to Choose a Truck Horn That Is Suitable and Compliant

When replacing a truck horn, drivers should note several factors to choose a suitable product that ensures quality and complies with the law.

- Check features and performance: Choose a horn with a clear, loud sound to ensure safety when participating in traffic.

- Choose a horn suitable for the vehicle design: Not all horns are compatible with all vehicles. Choose a horn recommended by the vehicle manufacturer.

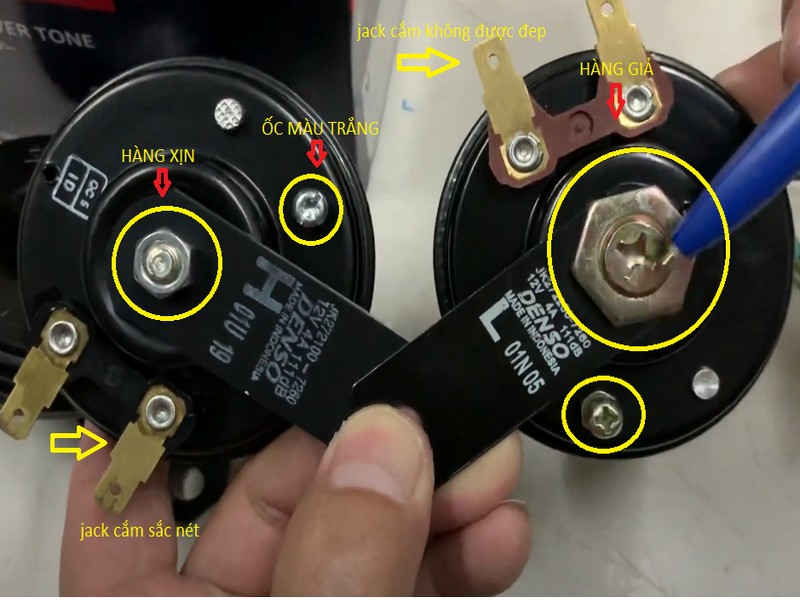

- Consider price and supplier: Buy horns from reputable suppliers to ensure quality and avoid buying counterfeit or imitation products.

Choose a reputable truck horn supplier

Choose a reputable truck horn supplier

X. Which Truck Horns Are Good and Reference Prices

There are many different truck horn brands on the market today. However, Denso and Bosch are two well-known brands that are highly regarded for their quality. These are good options that drivers should prioritize. Avoid using horns of unknown origin or horns with excessive sound intensity, high power, musical horns, etc., as they can damage the vehicle’s electrical system and violate regulations.

1. Denso Snail Horns

Genuine Denso snail horn

Genuine Denso snail horn

Denso is a leading Japanese automotive parts manufacturer, specializing in supplying parts to major car manufacturers such as Toyota, Mitsubishi, Nissan… Denso snail horns are popular in Vietnam due to their good quality, high durability, and stable sound. The reference price for a pair of Denso snail horns (2 pieces) at auto garages is about 400,000 – 600,000 VND.

2. Bosch Snail Horns

High-quality Bosch snail horn

High-quality Bosch snail horn

Bosch is a world-renowned automotive parts brand from Germany. Bosch snail horns are highly appreciated for their quality, durability, and powerful sound. Because they are less common than Denso in Vietnam, Bosch horns are less likely to be counterfeited. The reference price for a pair of Bosch snail horns (2 pieces) is equivalent to Denso, about 400,000 – 600,000 VND.

The above is detailed information about truck horns and related regulations. Xe Tải Mỹ Đình hopes this article has helped drivers better understand the issue of “how much is the fine for a loud truck horn” and how to use the horn legally and safely. If you have any truck-related issues that need advice, repair, or parts replacement, do not hesitate to contact Xe Tải Mỹ Đình for quick and professional support.