Trucks at material loading and unloading sites often carry bulk materials such as coal, ore, gravel, and cement. Accurately measuring the volume of materials is crucial for cost settlement. Previously, manual estimation or weight-based calculations were commonly used, which were prone to errors and labor-intensive. Neuvition’s LiDAR dynamic truck volume measurement solution offers a more effective approach.

LiDAR: Precise Truck Volume Measurement Technology

LiDAR is a 3D sensor capable of collecting precise three-dimensional spatial information. By using LiDAR, the system can create a 3D model of the truck and materials, thereby calculating the volume of goods automatically and quickly in real-time. This solution helps to:

- Improve work efficiency.

- Reduce losses due to measurement errors.

- Reduce costs and improve efficiency through automation.

- Output structured data as required.

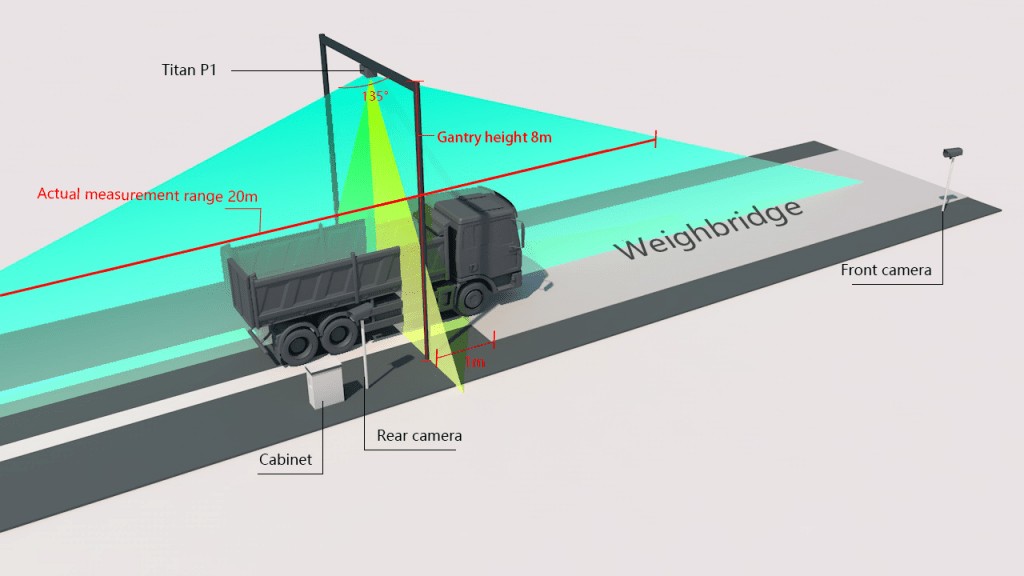

Illustration of a LiDAR system measuring truck volume

Illustration of a LiDAR system measuring truck volume

Dynamic Truck Volume Measurement System: How Does It Work?

The system scans and outputs data without requiring trucks to stop at material loading and unloading sites, including the length, width, and height of the vehicle. It generates a 3D point cloud image and processes volume measurements of goods based on this data. The system can output raw point cloud data and structured data according to user requirements. It uses the Ethernet/IP protocol to exchange data with existing equipment systems and monitor their status.

Hardware Configuration and Installation Requirements

The hardware includes high-resolution LiDAR, cameras (if license plate recognition is needed), and edge computing devices. Depending on the environment and vehicle size, 1-2 sets of equipment can be used to ensure full coverage of the scanning area.

Installation Requirements:

- Ambient temperature: -10°C to 50°C.

- Ambient humidity: 10% to 80%.

- A canopy above the LiDAR is needed to avoid direct sunlight.

- LiDAR is suspended on a gantry and scans vertically downwards. The recommended height of the gantry is above 8m.

- The installation location must be flat.

- Trucks should drive straight through the scanning area at a stable speed below 20km/h.

Applications and Features

The LiDAR dynamic truck volume measurement system is suitable for various types of trucks and bulk materials. It is applicable in scenarios such as ports, warehouse loading and unloading, and construction site transportation.

Software Functions:

- Real-time scanning and point cloud data collection.

- Measure truck length, width, and height.

- Identify license plate, truck head, bucket, and tail positions.

- Calculate volume and estimate material weight.

- Data management, query, and historical data recording.

- Provide SDK and API interfaces for integration and customization.

Benefits of Using LiDAR for Truck Volume Measurement at Material Loading and Unloading Sites

- Accuracy: More accurate volume measurement compared to manual methods.

- Efficiency: Automates the process, saving time and labor.

- Cost-saving: Minimizes losses due to measurement errors.

- Safety: Eliminates the need for personnel to directly contact materials.

- Flexibility: Suitable for various types of trucks and materials.

Neuvition offers Titan P1 and W1 series LiDAR models for this solution. Contact Neuvition for more details.