Forklift chains, also known as lift chains or hoist chains, play a crucial role in the operation of forklifts, ensuring smooth and safe lifting and lowering of goods. They are directly responsible for the performance and safety of the forklift. Understanding forklift chains, from inspection and maintenance to selecting and replacing the right type, is essential for all business owners and forklift operators.

Wholesale and Retail Supply of Forklift Chains | Lift Chains | Leaf Chains

Wholesale and Retail Supply of Forklift Chains | Lift Chains | Leaf Chains

High-quality forklift chains, ensuring performance and operational safety.

1. The Importance of Regular Forklift Chain Inspection

Forklift chains are among the components that bear the greatest load and operate continuously during forklift operation. Therefore, forklift chain inspection is an indispensable step before each work shift. This not only helps detect early signs of abnormalities, preventing the risk of sudden breakdowns that disrupt work, but also ensures absolute safety for operators and goods.

Inspecting forklift chains before operation to ensure safety

Inspecting forklift chains before operation to ensure safety

Forklift chain inspection is crucial for maintaining safety and efficiency.

Signs to note when inspecting forklift chains:

- Chain elongation: Excessive chain elongation (exceeding 3% of the standard length) is a warning sign requiring replacement. Chain elongation reduces load-bearing capacity and increases the risk of chain breakage.

- Damaged chain links and pins: Carefully inspect chain links and pins for cracks, breaks, wear, or deformation. Any damage can reduce chain strength.

- Signs of rust or corrosion: Humid or chemical working environments can cause rust and corrosion, weakening the metal structure.

- Unusual noises: If you hear strange noises from the chain when the forklift is operating, it could indicate dry chain, wear, or problems with related components.

To accurately check chain elongation, use a specialized chain measuring tool. If the measurement result shows elongation exceeding 3%, forklift chain replacement is necessary to ensure safety and work efficiency.

2. Guide to Choosing the Right Forklift Chains

Choosing the right forklift chains for each type of forklift and application is a key factor in ensuring smooth and safe lifting system operation. Each forklift model with different load capacities and lifting heights will require a chain type with corresponding specifications.

Image illustrating forklift chains on the mast

Image illustrating forklift chains on the mast

Forklift chains are an indispensable part of the mast lifting system.

Factors to consider when purchasing forklift chains:

- Lifting capacity: Determine the maximum lifting capacity of the forklift to choose a chain type with a corresponding or greater load capacity.

- Lifting height: The lifting height of the forklift affects the required chain length.

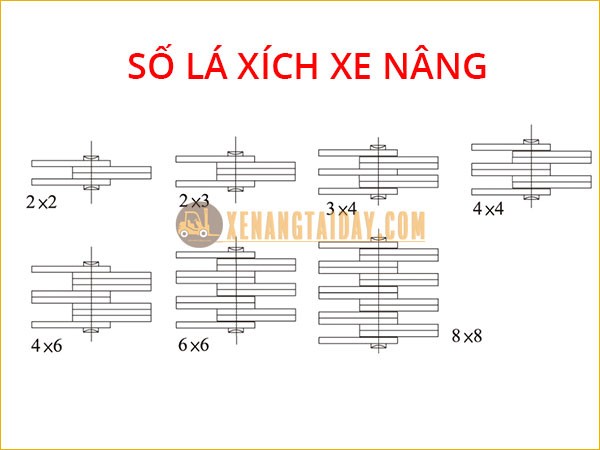

- Chain type: There are many types of chains on the market, such as leaf chains, roller chains, and bush chains. For forklifts, leaf chains are the most common, specially designed to withstand heavy loads and operate in harsh environments.

- Manufacturing brand: Prioritize choosing chains from reputable brands with clear origins to ensure quality and durability. Well-known brands often have strict quality control processes and use high-quality materials.

- Size and specifications: Compare chain specifications (pitch, number of leaves, leaf thickness, etc.) with forklift requirements to ensure compatibility. Refer to technical specification tables from manufacturers or reputable suppliers.

- Specific usage needs: The working environment and frequency of forklift use also influence chain selection. For example, forklifts operating in harsh environments with continuous heavy loads will require a chain type with higher durability and wear resistance.

Various types of chains available for different applications

Various types of chains available for different applications

Diverse types of forklift chains on the market, requiring the selection of the correct type for forklifts.

3. Structure and Outstanding Features of Forklift Chains

The structure of forklift chains typically includes three main components:

- Outer plates: The outer steel plates.

- Inner plates: The inner steel plates, alternating with the outer plates.

- Pins: Connect the inner and outer plates together, forming a flexible chain.

Names of forklift chain components

Names of forklift chain components

Detailed structure of a forklift chain, including plates and pins.

Distinctive features of forklift chains compared to other chain types:

- Superior load-bearing capacity: Forklift chains are made from special alloy steel, undergo heat treatment and precision machining, ensuring the ability to withstand heavy loads, even extremely heavy loads for heavy-duty forklifts.

- High durability and lifespan: Chains are designed to operate continuously in harsh conditions, withstanding high temperatures, friction, and high tensile forces.

- High precision: The technical specifications of forklift chains are strictly controlled, ensuring perfect meshing with the pulley system and mast, helping to operate smoothly and stably.

- Design suitable for masts: Chain size and shape are optimized for installation and smooth operation on the forklift mast.

Forklift chains are capable of bearing large volumes of goods

Forklift chains are capable of bearing large volumes of goods

Forklift chains are designed to bear heavy loads and operate durably.

4. Technical Specification Table of Common Forklift Chains

To help customers easily choose the right chain type, below is a technical specification table for some common forklift chains:

Wholesale and Retail Supply of Forklift Chains | Lift Chains | Leaf Chains

Wholesale and Retail Supply of Forklift Chains | Lift Chains | Leaf Chains

| No. | Chain Type | Number of Leaves | Pitch (mm) |

|---|---|---|---|

| 1 | Forklift Chain BL423 | 2 x 3 | 12.70 |

| 2 | Forklift Chain BL434 | 3 x 4 | 12.70 |

| 3 | Forklift Chain BL446 | 4 x 6 | 12.70 |

| 4 | Forklift Chain BL523 | 2 x 3 | 15.875 |

| 5 | Forklift Chain BL534 | 3 x 4 | 15.875 |

| 6 | Forklift Chain BL546 | 4 x 6 | 15.875 |

| 7 | Forklift Chain BL623 | 2 x 3 | 19.05 |

| 8 | Forklift Chain BL634 | 3 x 4 | 19.05 |

| 9 | Forklift Chain BL646 | 4 x 6 | 19.05 |

| 10 | Forklift Chain BL823 | 2 x 3 | 25.40 |

| 11 | Forklift Chain BL834 | 3 x 4 | 25.40 |

| 12 | Forklift Chain BL846 | 3 x 4 | 25.40 |

| 13 | Forklift Chain BL1023 | 2 x 3 | 31.75 |

| 14 | Forklift Chain BL1034 | 3 x 4 | 31.75 |

| 15 | Forklift Chain BL1046 | 4 x 6 | 31.75 |

| 16 | Forklift Chain BL1223 | 2 x 3 | 38.10 |

| 17 | Forklift Chain BL1234 | 3 x 4 | 38.10 |

| 18 | Forklift Chain BL1246 | 4 x 6 | 38.10 |

| 19 | Forklift Chain BL1423 | 2 x 3 | 44.45 |

| 20 | Forklift Chain BL1434 | 3 x 4 | 44.45 |

| 21 | Forklift Chain BL1446 | 4 x 6 | 44.45 |

| 22 | Forklift Chain BL1623 | 2 x 3 | 50.80 |

| 23 | Forklift Chain BL1634 | 3 x 4 | 50.80 |

| 24 | Forklift Chain BL1646 | 4 x 6 | 50.80 |

Technical specification table of common forklift chain types on the market.

5. Guide to Measuring and Identifying Forklift Chain Types

To ensure you purchase the correct forklift chain type for your forklift, refer to the measurement and identification steps below:

Step 1: Measure the overall length of the chain, take an overview photo of the chain to preliminarily identify the chain code and number of leaves.

Overview image of the forklift chain to be measured

Overview image of the forklift chain to be measured

Overall view of a forklift chain for measurement to identify chain type.

Location of the chain code usually printed on the chain plate

Location of the chain code usually printed on the chain plate

Location of the chain code typically printed on the chain plate for identification.

Step 2: Measure the width and thickness of the chain plate.

Measuring the width of the chain plate with calipers

Measuring the width of the chain plate with calipers

Measuring the width of a forklift chain plate using calipers.

Measuring the thickness of the chain plate to determine specifications

Measuring the thickness of the chain plate to determine specifications

Measuring the thickness of a forklift chain plate to determine technical specifications.

Step 3: Measure the distance between two chain links (pitch).

Measuring chain pitch, the distance between chain pins

Measuring chain pitch, the distance between chain pins

Measuring the pitch of a forklift chain, which is the distance between pins.

After having the measured parameters, you can compare them with the technical specification table or contact reputable suppliers for advice and to purchase the most suitable chain type.

Conclusion:

Forklift chains are a critical component, directly affecting the operation and safety of forklifts. Regular inspection, maintenance, and choosing the right chain type not only help extend the chain’s lifespan but also ensure optimal working efficiency and user safety. When you need to buy quality forklift chains, contact Xe Tải Mỹ Đình via Hotline for the best advice and quote. We specialize in providing genuine forklift chains of various load capacities and sizes, suitable for all forklift models on the market.