The Power Take Off (PTO) plays a pivotal role in operating auxiliary systems on trucks, converting engine power into useful force for various applications. Especially for the Thaco Ollin truck line, choosing and installing the appropriate PTO specifications for Thaco Ollin trucks is crucial to ensure optimal working performance and vehicle durability.

What is a PTO and Why is it Important for Thaco Ollin Trucks?

PTO, short for Power Take Off, is an intermediate transmission mechanism that allows power to be drawn from the truck’s main engine to drive peripheral equipment. Basically, the PTO functions as an auxiliary gearbox, attached to the truck’s main gearbox. When the PTO is activated, it takes power from the engine and transmits it to auxiliary components via a Cardan shaft, hydraulic pump, or directly.

For Thaco Ollin trucks, the PTO is not just an optional component but also a decisive factor in the vehicle’s versatility. PTO enables Ollin trucks to:

- Operate hydraulic dump systems: Transforming a regular flatbed truck into a dump truck, suitable for construction work and transporting bulk materials.

- Install garbage compacting systems: Converting Ollin trucks into specialized garbage trucks, contributing to urban sanitation efforts.

- Use for traffic rescue vehicles: Providing power for winches, cranes, and other rescue equipment, assisting in resolving on-road incidents.

- Applications in other industries: Driving water pumps, air compressors, mobile generators, serving various industrial and agricultural sectors.

PTO power take-off unit on a truck, showing the installation position next to the gearbox and connecting parts

PTO power take-off unit on a truck, showing the installation position next to the gearbox and connecting parts

Types of PTO Suitable for Thaco Ollin Trucks

There are many types of PTOs available on the market, classified based on installation location, drive type, and power capacity. To choose the correct PTO specifications for Thaco Ollin trucks, consider the following factors:

- Installation Location:

- Side PTO: The most common type, installed on the side of the gearbox, easy to install and maintain. Suitable for many common applications such as dump trucks and garbage compactors.

- Rear PTO: Installed at the rear of the gearbox, often used when more installation space is needed for pumps or other auxiliary equipment.

- Top PTO: Less common, installed on top of the gearbox.

- Drive Type:

- Mechanical PTO: Driven by gears and Cardan shafts, powerful and durable, suitable for high-power applications.

- Hydraulic PTO: Uses a hydraulic pump for drive, flexible in controlling speed and force, suitable for applications requiring precise control.

- Pneumatic PTO: Uses compressed air for activation and control, typically used for light-duty applications with low power requirements.

- PTO Power Capacity: The PTO power capacity must be appropriate for the Thaco Ollin truck’s engine power and the power requirements of the auxiliary equipment. Careful calculation is needed to ensure the PTO operates effectively and does not overload the drivetrain.

Technical PTO Specifications to Know When Installing on Thaco Ollin Trucks

To ensure smooth and efficient PTO installation and operation on Thaco Ollin trucks, it is crucial to understand the following important PTO specifications for Thaco Ollin trucks:

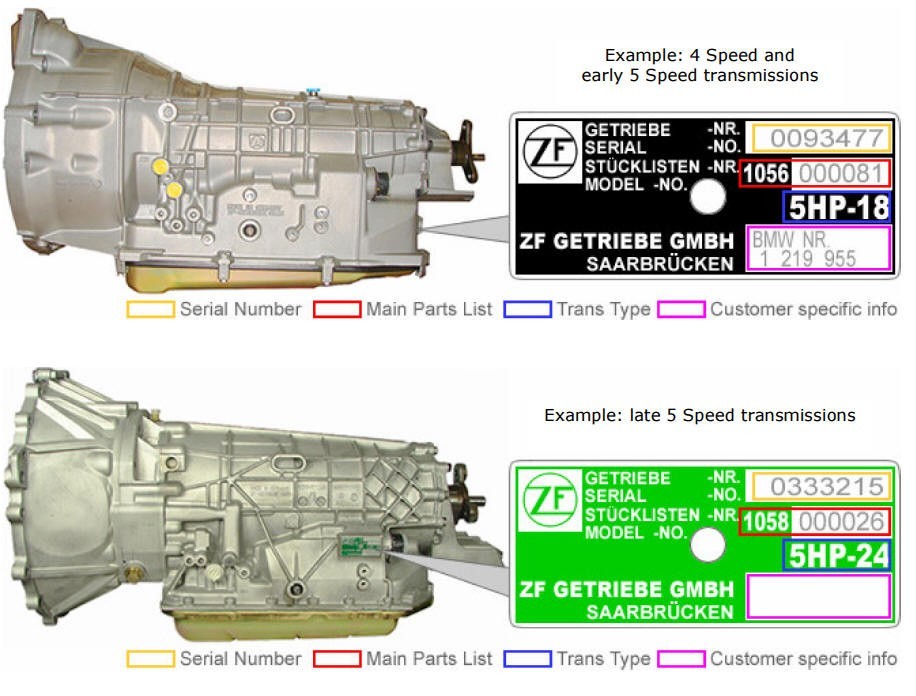

- Thaco Ollin truck gearbox code: This is the most important information for selecting a compatible PTO. Different Thaco Ollin truck lines and versions may use different types of gearboxes. The gearbox code is usually recorded on a label attached to the gearbox or in the vehicle’s technical documentation.

- PTO flange type (SAE Standard): The Society of Automotive Engineers (SAE) has established flange standards for PTOs and hydraulic pumps. Common types include SAE type B (most common), SAE type A, SAE type C, SAE type D. Choosing the correct flange type ensures precise mating between the PTO and the hydraulic pump.

- Number of bolts and bolt hole size: The PTO mounting location on the gearbox typically has 6, 8, or 10 bolts. The number and size of bolts must be compatible with the selected PTO. 6 and 8 bolt patterns are SAE standards commonly found on manual and conventional automatic transmissions. 10-bolt types are usually only found on Allison automatic transmissions.

- PTO gear ratio: The PTO gear ratio determines the output speed of the PTO relative to the engine speed. The appropriate gear ratio will ensure the auxiliary equipment operates at optimal speed and power. For continuous duty applications, it is advisable to choose a PTO with a gear ratio that allows the PTO to operate at around 1100 RPM, combined with a hydraulic pump with appropriate flow and pressure.

- PTO output shaft type: PTOs have various output shaft types to connect to different driveline systems, including:

- Splined shaft: Direct connection to hydraulic pumps or other components with splined couplings.

- Keyed shaft: Connection to Cardan shafts or other flexible couplings.

- Tapered shaft: Less commonly used.

PTO installed at the rear of a truck gearbox, showing ample space for connection to the pump and hydraulic system

PTO installed at the rear of a truck gearbox, showing ample space for connection to the pump and hydraulic system

Choosing and Installing PTO for Thaco Ollin Trucks

Choosing the PTO specifications for Thaco Ollin trucks requires caution and technical understanding. To ensure you select the correct PTO type and install it correctly, you should:

- Clearly define usage needs: What do you need the PTO for? (dumping, garbage compacting, rescue, etc.). What are the power and speed requirements of the auxiliary equipment?

- Consult with experts: Contact Thaco truck dealerships or reputable PTO suppliers for advice and support in choosing the right PTO for your Ollin truck model. Provide the gearbox code for the most accurate consultation.

- Choose reputable PTO brands: Well-known PTO brands such as Parker, Bezares, Muncie, etc., ensure high quality and durability.

- Install at a professional garage: PTO installation should be performed by experienced technicians to ensure technical correctness, safety, and efficiency.

Maintaining Thaco Ollin Truck PTO to Ensure Performance

For durable and efficient PTO operation, regular maintenance is crucial. Simple PTO maintenance tasks include:

- Checking for oil leaks: PTOs typically use gearbox oil for lubrication. Regularly check for oil leaks at seals and gaskets.

- Cleaning and lubrication: Periodically remove the hydraulic pump, clean it thoroughly, and apply grease to the pump shaft.

- Checking for noise: When the PTO is operating, if there is an unusually loud noise, check the internal gears for wear, jamming, or chipping.

- Changing PTO oil (if applicable): Some PTO types have a separate oil reservoir, requiring periodic oil changes according to the manufacturer’s recommendations.

- Checking and tightening bolts: Ensure the bolts holding the PTO are tightened to the correct torque to prevent leaks and vibrations.

PTO maintenance should be performed concurrently with regular Thaco Ollin truck maintenance to save time and ensure the vehicle is always in optimal operating condition. Listening to driver feedback on any unusual PTO symptoms is also an effective way to detect problems early and take timely corrective action.

Conclusion:

Choosing and installing the appropriate PTO specifications for Thaco Ollin trucks is a smart investment, helping to optimize operating capabilities and expand the application range of the vehicle. By understanding the technical information, choosing quality products, and performing regular maintenance, you will ensure the PTO system operates efficiently and durably, contributing to improved economic efficiency and longevity of your Thaco Ollin truck.